Partnering with a third-party logistics provider (3PL) that is near an inbound port creates many options for your company’s products when it comes to logistics strategies. A 3PL can receive your containers, provide storage for your products, and return the container within quick windows to avoid fees. Another option is to remove the warehouse element and use the 3PL for transloading and deconsolidation.

What is Transloading?

Transloading is the process of moving inventory from one form of transportation to another. It is similar to intermodal transportation but with intermodal, the cargo does not leave the container. Transloading often involves the 3PL unloading your container and providing additional services, such as processing, sorting, palletizing, and labeling before reloading onto the new form of transportation. Previously, transloading’s primary benefit was lowering costs because the contents of several shipping containers can be moved into a smaller number of 53’ trailers. However, with customer expectations for fast shipping on the rise, the benefit of efficient distribution and lower order-to-delivery times are just as valuable.

Transloading and Deconsolidation Services

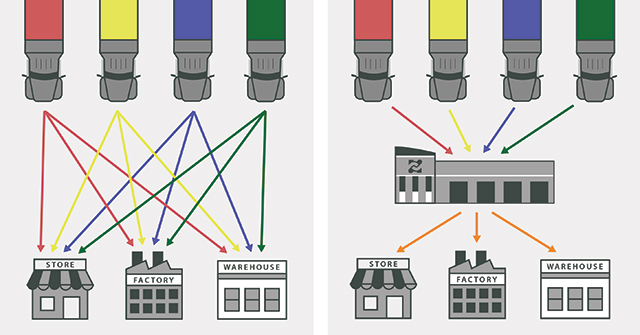

Companies often need both transloading and deconsolidation services for their containers. Deconsolidation is the process of breaking up a large load into smaller shipments by SKU or purchase order for distribution. The smaller shipments are then loaded on different trailers or containers to be transported to their appropriate destinations. Small shipments can also be combined into a single large load, a process called consolidation. Shippers who use an LTL carrier save a lot of money using distribution centers or hubs where their smaller shipments can be combined with other LTL shipments heading to a specific destination.

Hub-and-Spoke Model

The hub-and-spoke model is ideal for clients who have customers spread out across a wide geographic region or use a network of 3PLs. It simplifies the distribution process by creating a central point for organization (the hub) instead of having one truck delivering one shipment to many spread out locations. This can also be a good strategy for companies that only need one warehouse. Outsourcing to a 3PL warehouse with a central location provides a competitive advantage when using a single location because of the short transit times to reach a geographically spread-out customer base (the spoke). Kansas City is growing as a distribution hub because of its transportation advantages. It is located at the intersection of four major U.S. interstate highways and is the only metro area that can reach 65% of the U.S. population in 2 days and 100% in 3 days.

Utilizing a Heavy Haul Corridor

Transloading and deconsolidation at a facility located within an overweight corridor can be a strategic play for companies that ship heavier products. In the U.S., trucks are limited to a gross vehicle weight of 80,000 pounds, which only allows for a maximum container weight of 44,000 pounds with 40,000 pounds being standard to ensure weight limit is not exceeded. Keeping containers at or below the standard weight allows them to be transported on U.S roads without transloading and deconsolidation first, but many companies weigh out before they cube out (reach the 40,000-pound weight limit before filling their container). These companies are paying to ship empty space and a higher number of containers.

Businesses that partner with Beyond Warehousing can ship containers up to 58,000 pounds with no additional fees compared to a standard 40,000-pound container. How? Our warehouse is located less than one mile from the BNSF intermodal facility and within an overweight corridor. This allows overweight containers to be moved over the road to our facility where we can provide transloading and deconsolidation services before sending the product to its next destination. We can also provide other warehousing services for companies looking to have product conveniently stored in a central location. Contact us to find out how you can benefit from our strategic location and quality services.